But heatbeds are still quite effective because they allow building a strong warp-free foundation that resists warping stresses induced by the cooler zones higher up in the print. Just a quick video tutorial on how to fix the issue of your 3D printers build plate not heatingProducts used some are affiliate links - no extra charge to.

How To Remove Exess Filament From Bed After Removing Model 3d Printing Stack Exchange

However higher speed could also cause the nozzle to hit a previously printed part which may damage the print due to the heated nozzle.

How heat build plate affects material printed. Heat sink printed with TCPoly Ice9 filament. Heat treatment may affect the dimensions of the parts so most people prefer to heat-treat parts before they machinefinish them. Nowadays the majority of the 3D printers have them and they always need to be set to a certain temperature.

How do you increase plate adhesion. But a heated bed has a second side effect that can help reduce warping at the source and thats because the radiated heat will help keep the print warm. While you can often get ABS to adhere to bare heated borosilicate glass build plates the process is difficult and you will more than likely experience warpingcurling or failed prints due to the print breaking free from the glass mid-print.

Thus the first layer of an object can be printed before the build plate lowers and the process repeats with deposition of the polymer to fashion the second layer and so on. The bed material must stick to the plastic coming out of the extruder. This occurs when the weight of higher layers squish lower layers before they have cooled sufficiently.

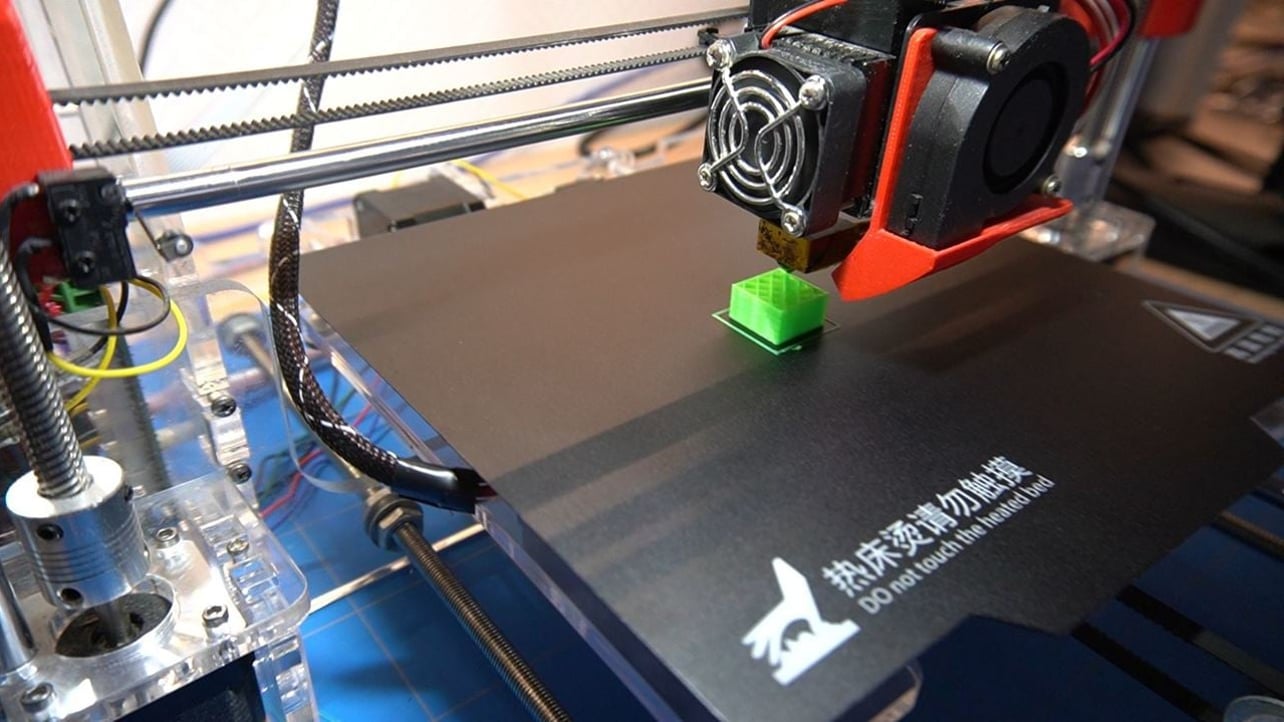

Can it cause warping. In some cases print orientation can contribute just as much to the strength of a print as the density. Otherwise the partially-printed part will slide around.

Heat treatment can easily cost 500 to 2000 depending the material and how many parts are. Material is 4mm thick T6061-T6 aluminum alloy. In general PLA filament settings have an optimal printing PLA temperature range from about 185C to about 205C.

One company in particular stands out as they claim to have a material that is 50 times more thermally conductive than standard filaments. Plate is compatible with MK2 MK2A and MK2B heat bed PCBs. Does room temperature affect printing.

The model on the left has supports printed with PVA it requires a support wall. When printing supports with the build material removal of support is more important and no extra support wall is used. Even though the recommended PLA print.

The conventional methods involving rafts skirts and brims greatly help in increasing plate adhesion. The model on the right is printed with the build material it does not have a wall to ease the post processing. The American Society for Testing and Materials ASTM just released a standard for thermal postprocessing of metal AM parts.

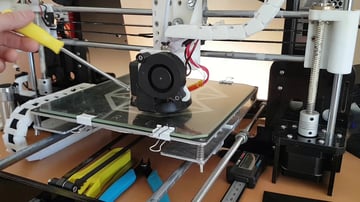

A heated bed helps to prevent warping Source. If youre using 175mm as opposed to thicker 285mm or 300mm your optimal print will be closer to the lower end of this PLA filament temperature range. This page is for general information pertaining to both heated and unheated print surfaces.

Ultimaker Heated beds are crucial to 3D printing. The build chamber is first filled with inert gas and then heated to the optimal print temperature. A centimeter up from the build plate the print is typically much closer to ambient temp than it is to the bed temp.

He came up with a couple of ways to fix the problem. The temperature of the build plate is cooler than that of the printhead such that the polymer solidifies on contact with it. Heated build chambers are thus much more effective for large prints.

Initial layer print speed. The laser scans the cross section of the part selectively bonding the metal particles. If a print is warping off the build plate increasing the bed temperature 5 degrees at a time can help.

However too much heat and the print can lose dimensional stability. You see that largest factor in how much a print is going to warp is roughly speaking the difference between the plastics glass transition temperature and the cooled down. If you need to 3D print a part that is meant to be exposed to high temperatures then there are few materials more suited for the job than nylon.

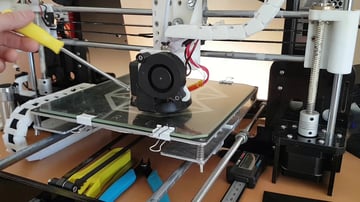

Aluminum Heated Build Plate It was designed to be used as heated build surface of typical 3d printer with 200 x 200 mm XY build area. Nylon is one of the most heat-stable filaments used in FDM printing. For information specific to heated build surfaces see the surface materials section of the heated bed page.

Thing uses countersunk mounting screws to. This can be prevented by using Z-hop when retracting. Nylon prints at a very high temperature even higher than ABS.

Plate has sufficient thickness to prevent twists and to maintain high flatness across whole building area. Prints at very high temperature. The travel speed for the initial layer differs from the rest of the print to ensure proper adhesion with the build plate.

Some plastics such as ABS can have dramatic effects due to the difference in temperatures. This post will analyze how both filling density and orientation contribute to an objects relative strength by measuring the force required to break a 4 x 34 x 14 printed part. Yes room temperature plays a major role in affecting printing.

Starting with the extruded materials there are a few options available. A thin layer of metal powder typically 50 μm is spread over the build platform. The bed material needs to satisfy two somewhat contradictory goals.

None will print a model without generating any support material Touching Build Plate will only generate support material that originates on the build plate for instance an upright letter T. ABS should NEVER be cooled with a layer fan. This is of course not limited to this brand of printers and affects all extruder-based hardware using the PLA as a source material.

How To Fix Warping Ultimaker Support

Build Plate Adhesion How To Get Your Print To Stick To The Build Plate Ultimaker Support

3d Printing Guides Everything About Heated Beds Tom S 3d Printing Guides And Reviews

Monoprice Select Mini 3d Printer V2 Gear Hungry Monoprice Printer Best 3d Printer

Pin On 3d Printer Cyber Monday Deals

Build Plate Adhesion How To Get Your Print To Stick To The Build Plate Ultimaker Support

21 3dbenchy Boat 3d Printed On Zyyx 3d Printer Plate In One Go V01 3d Printing Diy 3d Printer Prints

Build Plate Adhesion How To Get Your Print To Stick To The Build Plate Ultimaker Support

Why Can T I Get 3d Printed Parts To Stick To The Bed Airwolf 3d

3d Printer Glass Bed What To Consider Which To Buy All3dp

Magnetic Vs Polypropylene Build Plate The Differences All3dp

3d Printer Bed Adhesion All You Need To Know All3dp

899 00 Watch More Here Flashforge 3d Printer Creator Pro Metal Frame Structure Optimized Build Platform Dua Best 3d Printer 3d Printer For Sale 3d Printer

Why Can T I Get 3d Printed Parts To Stick To The Bed Airwolf 3d

How To Fix Warping Ultimaker Support

Heat Beds In 3d Printing Advantages And Equipment Boots Industries

Komentar

Posting Komentar